ITCS offers a wide range of advanced NDT services which are carried out by highly qualified technicians who are accredited to perform their work during the manufacturing phase of your products or equipment or when the units or systems are shutdown.

- ACFM

- TOFD and Phased Array ultrasonic testing

- Acoustic emissions

- Eddy current

- IRIS, RFT, Flow Loss

- Pulsed Eddy Current (PEC)

| ACFM (ALTERNATING CURRENT FIELD MEASUREMENT) Technique de contrôle électromagnétique de mesure de champ d’un courant alternatif

|

|

| Time Of Flight Diffraction (TOFD) TOFD is an inspection method that can be used for weld testing or to inspect sheet metals with thicknesses ranging from 6 to 300 mm. To do so, it relies on the diffraction phenomena generated by defect edges. This is supplied in the form of a B-Scan view (cross-section of the thickness), represented as a grey-scale image, which serves to more easily analyse the relatively low amplitude signals. |

|

| Phased Array Ultrasonic Testing (PAUT) Phased Array Ultrasonic Testing involves using probes which contain multiple elements, i.e. a phased array probe. Each element can be controlled separately and simultaneously as a transmitter and receiver. Based on this programmable control, the beam from the probe can be swept (inspection of a large volume of material), focused (several focusing depths) and deflected (focusing in a point with several angles) electronically. |

|

| Acoustic Emission (AE) Testing Acoustic emission testing is a quick and versatile NDT technique. It is especially appropriate for checking the integrity of large structures while significantly lessening the testing time and costly shutdowns.There are many applications for AE: testing the integrity of pressure equipment (regulatory requalification as a replacement for hydraulic testing) such as autoclaves, sterilisers, freeze dryers, heat treatment ovens, tanks, chemical reactors and storage bins.

|

|

| Eddy Current Testing (conventional ECT or ECA) Eddy Current Testing is an electromagnetic testing method that is generally used to inspect ferromagnetic materials. It is suited to the detection of surface discontinuities with a high sensitivity to small flaws and defects given the modification of the induced magnetic field. This method does not require any couplant or surface preparation.

|

|

| IRIS The Internal Rotary Inspection System (IRIS) is a submerged ultrasonic testing method. The 0° longitudinal wave transducer is placed on a probe head fitted with a centring system and a turbine comprising a mirror sloped to 45°. The probe is moved and rotated by the water being supplied through a tube. This method is used to detect and locate missing material type defects such as pitting, erosion, corrosion, etc. |

|

| Remote Field Testing (RFT) This method is an alternative to eddy current testing and is suitable for applications on all types of exchanger tubes made from ferromagnetic steels. Indeed, the heterogeneous appearance of the ferromagnetic structure causes significant interference to the eddy current signal thereby making it difficult to distinguish the defects from the background noise. RFT helps to detect internal or external missing material type defects and cracks. |

|

| Flow losses This method relies on local magnetisation of the material to be examined (testing probe). It serves to detect thickness losses or the presence of discontinuities (variation in the distribution of the detected flows). It is used to inspect cooling tower tubes with external fins (made from ferromagnetic steel) and identify internal or external missing material type defects and cracks. |

|

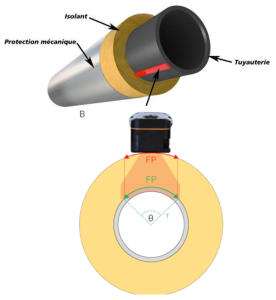

| Pulsed Eddy Current (PEC) As a non-intrusive testing method, PEC serves to detect, locate and assess the damage without removing the coating in order to search for corrosion such as:

|

|